rotary kiln tire material

2021-08-23T02:08:07+00:00

rotary kiln tire material seniorenbeirathuerthde

rotary kiln tire material CHAENG uses ZG45 and ZG42CrMO materials to ensure the strength and toughness of the rotary kiln tyre 3 Double medium quenching process treatment After dualmedium quenching process the rotary kiln tyres of CHAENG have good wear resistance and can adapt to various harsh working environments 4 Customized according to rotary kiln tyre, also called rolling ring, is one important part of rotary kiln it transmits all gravity of rotary barrel (including refractory bricks, internal Kiln Tyre greatwallcastingRotary Kiln Tire Material Kiln tyre with a simple structure, easy manufacturing and routine maintenance Our company according to customer drawings processing a variety of rotary kiln tire, optimized process and excellent quality, to ensure that the processing of the existing rotary kiln tire and kiln equipment wellmatchedRotary Kiln Tire Material kathkirchegauweinheimde

Rotary Kiln Tire Material From Turkeyrotary Kiln

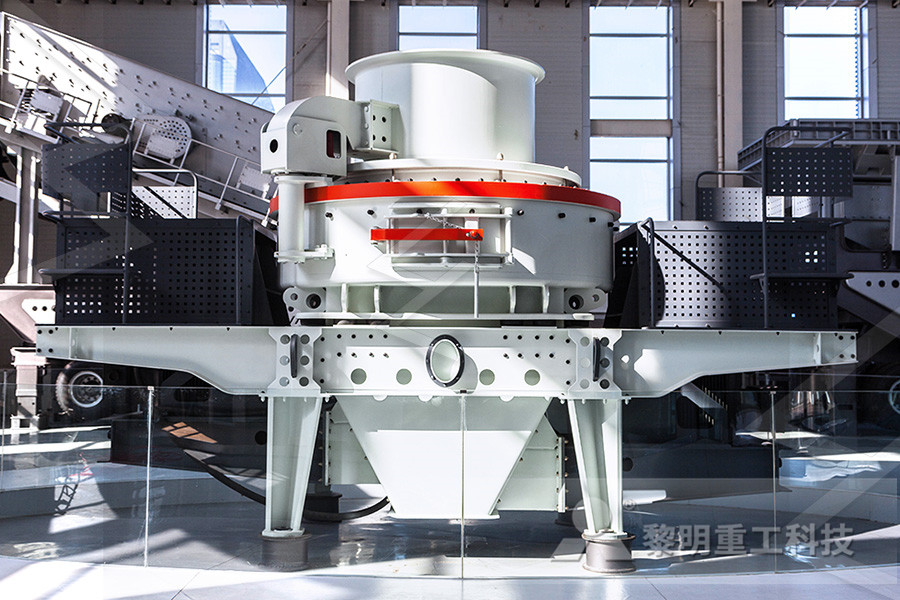

Rotary Kiln And Batch Pyrolysis Of Waste Tire To Produce Mar 01 2016 the rotary kiln pyrolysis of a waste tire was founded at adiyaman region known as kudret inkar waste tire recycle co turkey in this system the waste tire is pyrolized and then condensated by a heat exchange system containing three heat exchangers such as high c medium c and low 75200 c Therefore, CHAENG uses highquality cast steel materials and strictly controls the quality of each step of the process, to ensure that the rotary kiln tyres have sufficient strength, durability, and rigidity specification Weight 180 Tons Material Steel ZG45, ZG42CrMo Application Rotary kiln, rotary dryer, etcKiln tyre CHAENGCheap Rotary Kiln Rolling Ring Tyre Manufacturers rotary kiln rolling ring tyre product description The ring tyre is mounted on the cylinder and rotates on the carrier The ring tyre is connected to the kiln body by a pad a stopper or the like The wheel is a sturdy large steel ring that fits on the cylinder and supports the full gravity of the rotary kiln including kiln bricks and materialsRotary Kiln Tyre Material familienzentrumstjosephde

Functions and damage types of rotary kiln tyre

1 High strength, good durability CHAENG uses ZG45 and ZG42CrMO material, which can guarantee the strength and toughness of kiln tyre, so as to play a better supporting role 2 Use advanced dualmedium quenching process Rotary Kilns also have cylindrical steel castings, known as tyres, attached to the shell, which obstruct the shell monitoring system If a hot spot forms under a tyre, then the instrument will not detect it Consequently, a local hot spot monitor should be installed at each tyreRotary Kilns Williamson IRRotary Kilns also have cylindrical steel castings, known as tyres, attached to the shell, which obstruct the shell monitoring system If a hot spot forms under a tyre, then the instrument will not detect it Consequently, a local hot spot monitor should be Rotary Kilns Williamson IR

Material and energy flows in rotary kilnelectric furnace

The rotary kilnelectric furnace process is the one of the most widely adopted technological process for ferronickel smelting production A schematic of the RKEF process with rotary dryer, rotary kiln and electric furnace is shown in Fig 1As depicted, the RKFF process involves three main processes: the dehydration process in rotary dryer; the roasting and pre Rotary Kiln Tyre Kiln Riding Ring Mar 14 2018nbspkiln tyre introduction rotary kiln tyre is also called rolling ring or riding ring which is one of the main components on the rotary kiln the role of the kiln tyre is to pass the entire gravity of the cylinder including the refractory bricks internal equipment and material gravity to the support roller and the cylinder can rotate smoothlyRotary Kiln Tyre Material sukosmetikde The role of the rotary kiln tyre (also known as the rolling ring) is to transfer the weight of the cylinder (including refractory bricks, internal devices and materials, etc) to the support roller, and to enable the cylinder to rotate smoothly on the support roller, so the kiln tyre must have sufficient strength and durability At the same time, the rotary kiln tyre is a part that Functions and damage types of rotary kiln tyre

Rotary Unit Tires Industrial Kiln Dryer Group

Parts / Tires Much like the tires on your vehicle, rotary unit tires play a vital role in the continuation of your process Industrial Kiln Dryer Group® has the capability to design new, single, twopiece or fourpiece tires for your process– no matter the make or model of the unit We have both domestic and international supplier Refractory material for cement rotary kiln hoods rsrefractory material for cement rotary kiln hoods rsAug 15 2020 refractory material for cement rotary kiln hoods august 15 2020 by rsrefractorycastable for some large rotary kilns the heat load on the lower part of the kiln, rotary kiln tire surface wearRotary Kiln Tire Surface Wear, Rotary Kiln Tire migration, also known as tire creep, is the difference in the circumferential distance travelled between the tire and shell in one revolution ie the amount that the tire lags or “creeps” behind the shell Causes of kiln tire creep: • Wearing of kiln components that reduces the diametrical clearance between the tire and shellRotary Kiln Maintenance – Get the most out of your

Why Rotary Kiln Tyre Cracks Reamor Industry

Rotary kiln shell usually has the following conditions: 1 The cylinder under the tyre has necking phenomenon in different degrees, and the continuous operation will easily cause cylinder fracture 2 The cylinder body at the intersection of cooler and rotary kiln discharge port is prone to fracture accidentPDF On Jul 10, 2019, T A Duyun and others published Modeling a repair machining of a rotary kiln tire Find, read and cite all the research you need on ResearchGate(PDF) Modeling a repair machining of a rotary kiln tire rotary kiln operations Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln, calciner, dryer, incinerator, digester and cooler application For questions or problems with your specific application please contact North American Kiln for assistanceRotary Kiln Maintenance Procedures Anion Specialty

TireDerived Fuel Scrap Tires US EPA

Tires can be used as fuel either in shredded form known as tirederived fuel (TDF) — or whole, depending on the type of combustion device Scrap tires are typically used as a supplement to traditional fuels such as coal or wood Generally, tires need to be reduced in size to fit in most combustion unitsUnity3D中Material与ShareMaterial引用的区别 我们在使用Unity引擎的时候,有时候需要去修改某个物体上的Material,在Unity的Renderer类里,提供了两个方法接口供我们使用。 Renderermaterial和RenderersharedMaterial 那么这两货有什么区别呢!Unity3D中Material与ShareMaterial引用的区别 简书The Rotary Kiln T ire is also called the rolling ring Its function is to transfer all the gravity of the cylinder (including the gravity of refractory bricks, internal devices and materials) to the supporting roller, and make the cylinder rotate smoothly on the supporting roller The belt should have sufficient strength and durabilityRotary Kiln Tire HENGIN

Rotary Kiln Tire Material From Turkeyrotary Kiln

Rotary Kiln And Batch Pyrolysis Of Waste Tire To Produce Mar 01 2016 the rotary kiln pyrolysis of a waste tire was founded at adiyaman region known as kudret inkar waste tire recycle co turkey in this system the waste tire is pyrolized and then condensated by a heat exchange system containing three heat exchangers such as high c medium c and low 75200 c Examining upgrade options when rotary kiln tires are mounted on the kiln shell with no filler bars Andrew Wisner, Abstract Rotary kilns are some of the largest pieces of processing equipment in the world that are utilized in many industries globally to refine raw materials into useful productsExamining upgrade options when rotary kiln tires are Cement rotary kiln tire inspection pdf 6 the tire and support roller radiuses do not vary by more than 010 a tapered tire or roller tilts the plane of the tire relative to the kiln axis causing high tire stop block loads and excessive support pad wear 7 the shell must be assessed for doglegs that cause pier load variations as the kilnChina Cement Rotary Kiln Tire Inspection Pdf

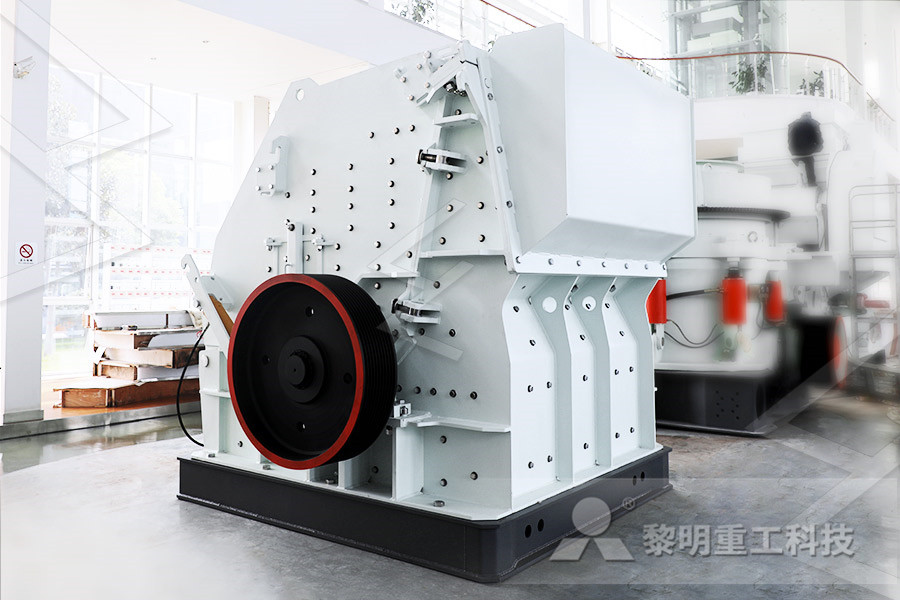

IBUtec The Rotary Kiln Experts for Trials and Production

Rotary kilns (sometimes called calciners or rotary furnaces) are used for thermal treatment processes such as calcination, sintering, pyrolysis and firing, as well as for oxidation and reductionThese treatments can be applied to powders, granulates, suspensions and green bodiesA rotary kiln consists of a cylindrical, rotating body mounted between stationary Material For Cement Kiln Tire Manufacturing 1311 kiln tyre products are offered for sale by suppliers on alibabacom of which cement making machinery accounts for 16 forging accounts for 3 and other rubber processing machinery accounts for 1 a wide variety of kiln tyre options are available to you there are 512 suppliers who sells kiln tyre on Material For Cement Kiln Tire Manufacturingmaterial inside the rotary kiln is considered to be unevenly distributed (ie bed motion) as shown in Fig3 qd qm Qb Qa! 0 270 100 200 90 217 143 Y X Rotating direction M0 N0 Fig 3 Twodimension model with uneven load distribution The distributed loads q d and q m represent the selfweight of kiln and raw material, respectively Q aand Q bANALYSIS AND REDESIGN OF SPOKES ON ROTARY KILN

Devolatilization and Combustion of Tire Rubber and Pine

particles of tire rubber and pine wood with equivalent diameters of 10 mm to 26 mm are investigated in a pilot scale rotary kiln able to simulate the process conditions present in the material inlet end of cement rotary kilns Investigated temperatures varied from 700 to 1000 °C, and oxygen concentrations varied from 5% v/v O 2 to 21% v/v O 2 The tyre not only facilitates the rotary motion of the kiln but is also responsible for maintaining its roundness and consequently the mechanical integrity of refractory The shell at the points of support would collapse were it not for the girdling effect of the tyreWhy Tire Lubrication is Needed easybarlube Phillips Kiln Services) as shown in the first graphic above Posted by Walter Gebhart in Shell Flex at 12:13 Comments (0) Trackbacks (0) Monday, May 10 2010 Roller and Tire grooving or banding Ali T writes; Is there any reason for circumferential marks on tire and rollers? A ridge on the kiln tire andPhillips Kiln Services Blog International Cement Review