different capacity of cement ball mill

2022-04-10T07:04:29+00:00

Cement Ball Mill JXSC Machine

10/12/2019 The equipment of ball mill used in cement plant includes vertical cement mill, roller press and ball mill, etc The cement ball mill in cement plant is usually divided into 24 silos, the most representative of which are the “new type of high fineness cement ball mill” and “open flow high fineness cement ball mill”13/02/2017 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside Ball Mills Mineral Processing MetallurgyQuantities of different constituents are, water = 04 * 1 part =04 * 0227 kg = 009 kg Cement = 1 part = 0227 kg Sand = 3* 1 part = 0683 kg If the sand used for this mix contained adsorbed water equal to 5% of weight of sand, the calculations would change as follows: Suppose 1 kg of mortar is to be preparedHow to calculate cement ball mill capacity Quora

different capacity of cement ball mill baculakonferencjapl

Cement Production Line Part III Machine Information Cement production line part iii machine informationsep , sinouniques raw material ball mill has a production capacity of th, a full transmission type, and a motor power of kw full transmission features can be customized to different specifications in terms of design, the structure is made a separate room which The cement ball mill has reasonable structure design, simple operation, large handling capacity and low failure rate The wearresistant parts are made of ultrawearresistant materials, which can reduce the exchange cost of the vulnerable parts and control your production and maintenance costCement Ball Mill Ball Mill For Sale Cement Mill AGICOAGICO is specialized in design and supplies equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD; Main equipments include: rotary kiln, grinding equipment(ball mill and vertical mill), crusher, cooler, preheater, conveyor equipment, dust collector, etcBall Mill for Cement Grinding Process

Use Cement Ball Mill Grinding Cement Clinker Cement Ball

According to the needs of different customers, there are two types of cement ball mill: openflow mill and circularflow mill The φ38×13 cement ball mill with doublesliding structure solves the problem of the similar product “the discharge end slide bearing temperature is too high to operate continuously”, which ensures the equipment can run continuously and stably for a long time 8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball Ball Mills an overview ScienceDirect TopicsChina Different Capacity of Cement Ball Mill Find details about China Mill Ball Mill from Different Capacity of Cement Ball Mill Jiangsu Pengfei Group Co Ltd Shop now Compare Different Types Of Cement Ball Mill How to determine the ball mill for cement production capacity has become a very important research object different types of cement ball mill different capacity of cement ball mill

Ball Mills Mineral Processing Metallurgy

13/02/2017 Ball Mill Capacity VS Rod Mill Capacity Until recently many operators have believed that one particular type of grinding mill had greater efficiency and resulting capacity than some other type However, it is now Capacity Of Cement Ball Mill Processing capacity:150426t/h Feeding size:≤13mm Appliable Materials: cement,ore dressing of ferrous metal,copper mine,ore,construction rubbish,ceramics etcAll grindable materials, various metal ores, non Capacity Of Cement Ball Millball MillAnswer (1 of 2): You can ask your vendor who made this machine It’s difficulty to calculate capacity of a machine or maximum capacity It’s depend on a lot of How to calculate cement ball mill capacity Quora

Use Cement Ball Mill Grinding Cement Clinker

The cement ball mill operation is more practical and the energysaving effect is better In terms of production capacity, the output of cement ball mill produced by us can be increased by 15% – 20% compared with the one made by other 2 Tph Ball Mills ball mill supplier of capacity 2 5 tph ball mill supplier of capacity 2 5 tph fuller ball mill 30 tph tfg fuller ball mill 30 tph stone crusher 30 tph bsc 30 ji ji case hammer mill cone crusher crushing capacity, get more info 30 tph ball mill manufacturers in india 20 tons per hour capacity ball mill in india, ball mill used to grind li ne in cement plant Capacity Of Different Ball Mill In TphCement ball mill capacity crusher in india calculation of cement ball mill capacity calculation of cement ball mill capacity jaw crusher for assaying rock ball mill wikipedia 2018 6 15 a ball mill is a type of grinder used to grind and blend materials for Chat Online Learn More Cement Grinding Mill Throughput Calculation What Is Throughput For A Cement Grinding Ball Mill calculation of capacity of cement mill ball grinding mill

Ball Mill for Cement Grinding Process

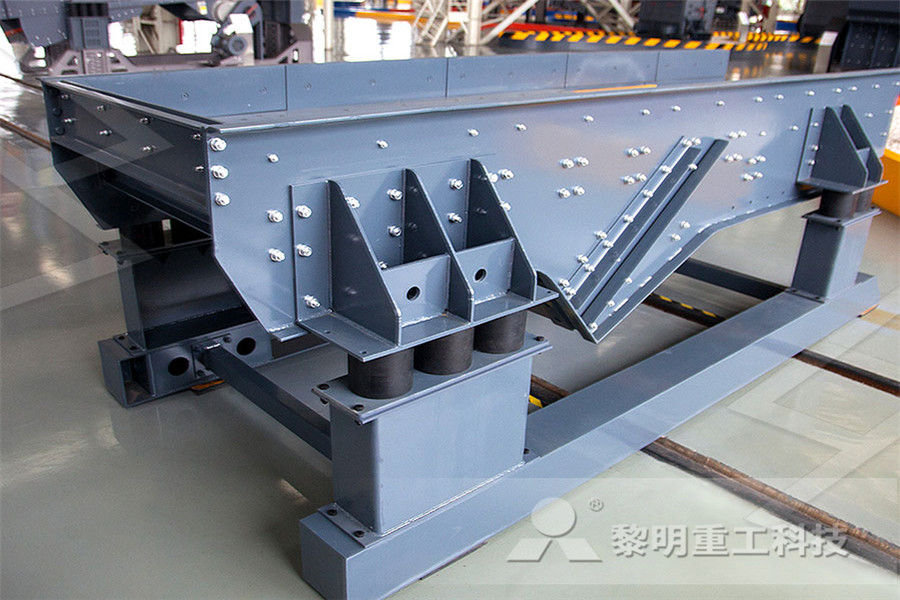

Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, Due to the different physical and chemical properties and microhardness of the materials (the grindability of materials in raw meals decreases in clinkers), the clinker discharged from the cement kiln must be pretreated to reduce its particle size so as to increase the output and reduce the power consumption of the ball millHow to Improve Cement Ball Mill Performance in Closed A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is Cement mill Wikipedia

Ball Mill Parameter Selection Calculation Power

30/08/2019 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature Capacity: 3385 t/h Free Material Testing Ball Mill Customization Turnkey Project GET FREE QUOTATION NOW ! Cement ball mill is a kind of ball mill grinder It is mostly used for grinding cement clinker and raw materials in cement plants and is also suitable for grinding various ores and other grindable materials Cement ball mills can be applied in the open Cement Ball Mill – Ball Mill In Cement Plant For Sale 05/11/2020 Vertical roller mill Vertical roller mill, also called cement vertical mill, it grinds raw materials by the movement between grinding roller, millstone and grinding device In general the grinding efficiency of vertical roller mill is 80% as much power as cement ball mill, reduce about 30% power consumption vertical cement mill3 Necessary Cement Milling Comparison Ball Mill

How To Increase Capacity Of Cement Ball Mill

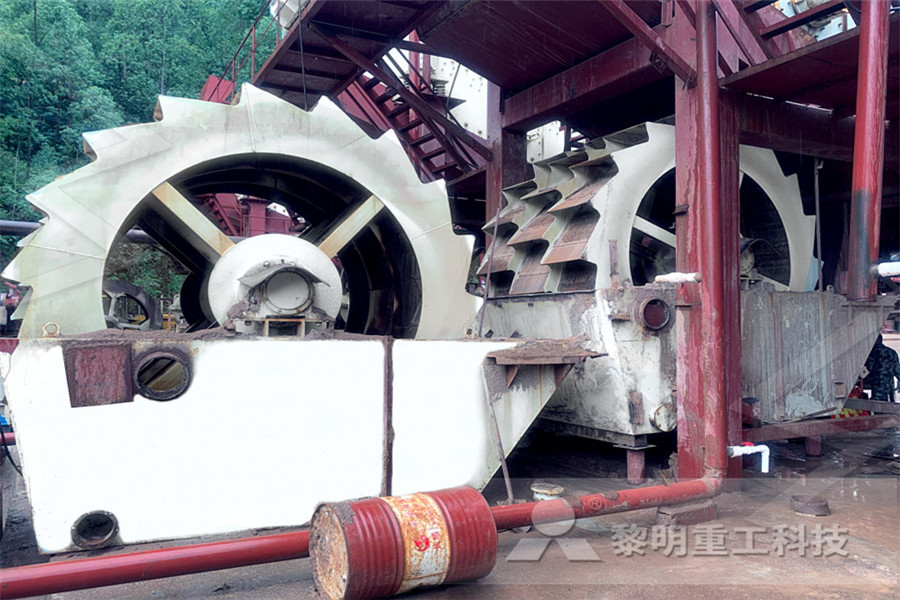

4 ways to increase the capacity of cement ball mill 1 Using cement crusher to reduce cement size 2 Using separator to select raw material with different particle siThe cement ball mill is mainly used for grinding the finished products and raw materials of cement plants and is also suitable for grinding various ore and other grindable materials in industrial and Get price how The mill is usually divided into at least two chambers, allowing the use of different sizes of grinding media Large balls are used at the inlet, to crush clinker nodules (which can be over 25 mm in diameter) Ball diameter here is in the range 6080 mm In a twochamber mill, the media in the second chamber are typically in the range 1540 mm, although media down to 5 mm are CementmillCement ball mill capacity crusher in india calculation of cement ball mill capacity calculation of cement ball mill capacity jaw crusher for assaying rock ball mill wikipedia 2018 6 15 a ball mill is a type of grinder used to grind and blend materials for Chat Online Learn More Cement Grinding Mill Throughput Calculation What Is Throughput For A Cement Grinding Ball Mill calculation of capacity of cement mill ball grinding mill

How to Improve Cement Ball Mill Performance in Closed

Due to the different physical and chemical properties and microhardness of the materials (the grindability of materials in raw meals decreases in clinkers), the clinker discharged from the cement kiln must be pretreated to reduce its particle size so as to increase the output and reduce the power consumption of the ball millCement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of seconds The drum is generally divided into two or three The cement mill Understanding Cement18/11/2008 Equations of the design By knowing the capacity quot;Cquot; {ton} of the feed; we can get approximately the length quot;Lquot; {mm} and diameter quot;Dquot; {mm} of the batch ball mill, form **D = 1242*(C) + 4857 **L= 8571*(C) + 1854 Volume of mill = ^2 The bulk volume of balls charge ratio to the volume of mill is known as {Filling ratio} and its range is {30 Ball Mill SlideShare

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber liners II chamber liners Stepped classifying Mill size 46 x 165 m L/D