st of cement mill drives

2023-02-21T15:02:37+00:00

Cement Factory Cost How Much Does It Cost To Start A

14/05/2020 According to the data we know, the total cost of a cement plant is estimated to be US$ 75 to US$ 100 per ton One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors, including the significant difference in cost of land, availability of limestone mines, etcGalbiati Group designs and manufactures main and auxiliary gear drives for mills and kilns with rigid electrowelded housings; carburized and quality DIN 6 profile ground teeth; high quality roller type bearingssized for at least 100000 hours Cement Mill Drives Galbiati GroupIn 2016, cement prices finally surpassed prerecession prices, which was about 111 US dollars per metric ton the year prior to the global recession The cement price per ton relies heavily on Cement price 20072020 Statista

Automation of Kiln Mill Drive in Cement Industry using PLC

01/11/2014 Cement plants are one of the largest consumers of energy Their electrical energy costs account for about 15 20 percent of the total production cost The large fans and motors used in the production process consume a major part of electrical energy With the use of Variable Frequency Drives (VFDs) the energy consumption can be reduced fromOur portfolio includes a wide range of low voltage drives, medium voltage drives, DC drives, scalable PLCs, motors, mechanical power transmission, and a selection of HMIs From crushers to fans, from separators to kilns Our drives and PLCs easily integrate into new or existing installations Global ABB service and support gives the 24/7 confidence you needCement ABB DrivesCement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, it often pays to operate cement mills only during "offpeak" periods when cheaper power is available This is also favourable for electricity producers, who can negotiate power prices with major users in order to balance their generating capacity over 24 Cement mill Wikipedia

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

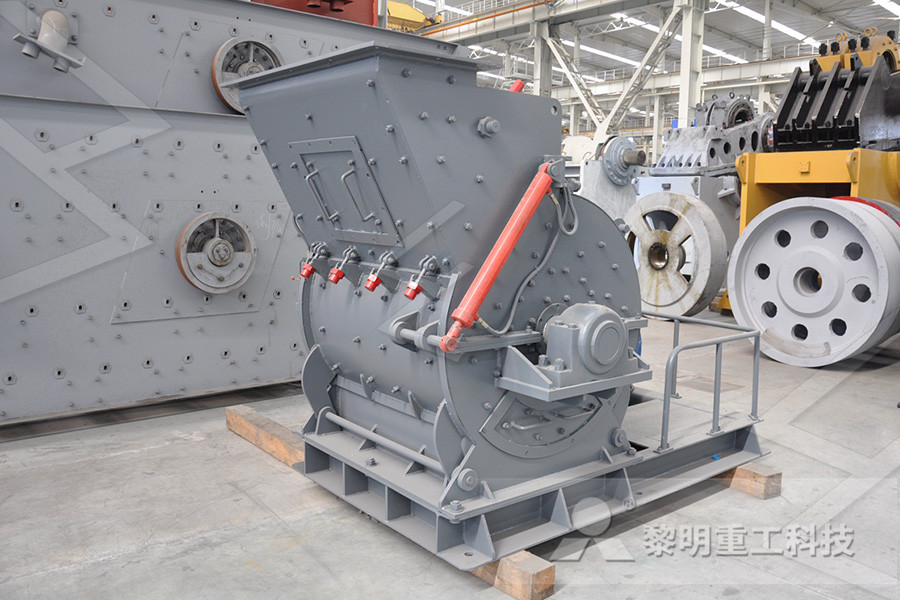

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished Layout Process Description Crusher Drives Compressor Drives Waste Gas Fan Drives Rotary Kiln Drives Cement Mill Drives Cement Making The raw materials for producing cement contain lime and silica as main components and ferric oxide as fluxing components The limestone mixed from the quarries is crushed and transported to the plant by dumper wagons The crushed Cement Mill Drives PDF Electric Motor Cement14/08/2018 The cost of resin bound driveways can be ambiguous because each project is completely different There are many different variables that may impact the cost of resin driveways A general guideline for an overlay installation however, is around £50£75 per m²The True Cost Of Resin Driveways Resin The Resin Mill

Understanding How The Indian Cement Industry Works

Cost Structure Of A Cement Company *Please note that the above rates are indicative and can change if the Market or the product is different So If A Cement Bag of Rs 350 Rs is sold Indirect Taxes levied by the government form almost Rs 75/ bag – Not to mention there are other taxes which are levied during the manufacturing stage such as Entry Tax, Cement Cess, Royalty etc drives for cement mill abstract: the cement industry depends on large electric motors to as energy cost continues to rise, it becomes increasingly important to Send Message Get a Quote Last News cost of cement grinding unit in india list of cement mills industry in pakistan cement mill tower cement ball mill manufacturers in chennai delhi to jaypee cement grinding drives for cement mill fdahessendeBIGGEST VERTICAL MILL IN THE WORLD OPERATING IN BRAZIL Capacity increase at Barroso – significant reduction of total cost per ton of cement // LafargeHolcim, one of the global players in the cement industry, had decided to increase its production capacities in Latin America, more precisely in the existing cement works in Barroso, BrazilBIGGEST VERTICAL MILL IN THE WORLD OPERATING IN BRAZIL

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL DRIVES

reliability and availability at competitive cost The first Gearless Mill Drive (GMD) with a power of 65 MW was installed 1969 in a cement milling process in the cement plant Le Havre in France In the first few years, the GMD was only used in the cement industry The GMD is also known as “wraparound motor” or “ringmotor” Almost 25 years later, the first GMD with 120 MW power Home crusher cement mill vertical roller mill flender gear box of w 106 3 flender vertical mill drives cost of 20 tph cement grinding vertical mill Reference List English complete 4 Exchange of cement mill drive Mills For Making Silica Flour Want To Buy Cement Plant Vertical Milling Machinery In Acid LM series vertical roller mill is one LM K mineral mill is suit for producing Cement Vertical Mill Drives Reference ListProcess Of Cement Mill Drives Cement Mill Packaging Shipping Sales by Category Integration of drives, instruments and intelligent electronic devices Reduced integration cost of disparate systems Safe monitoring of energized devices on operator screens cement, process control, [ protected] Get Price List Chat Online Solutions Hot Products get a quote Process Of Cement Mill Drives classiccenterregentalde

of electric drives in cement mills

Application Of Electric Drives In Cement Mill Direct drive is used for power transmission only when (a) Industrial Applications of Electric Motors 1791 (d) Any of the above 28Jun 17, 2020 Two fundamentally different philosophies exist to drive horizonal mills While the gear unit and the electric motor of a central drive are located at the front of the mill and take up a lot of space, theA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, The hardness of clinker is important for the energy cost of the grinding process It depends both on the clinker's mineral composition and its thermal history The easiestground clinker mineral is alite, so highalite clinkers reduce grinding costs, although they are more expensive to make in Cement mill WikipediaSpeed Of Cement Mill Drives ABB drives in cement Medium voltage drives for reduced ABB has been supplying variable speed drives for over 30 years Today, VSDs are used in a wide range of applications in the cement industry, such as: − Induced draft (ID)Speed Of Cement Mill Drives metallzauneskpl

Mines and cement works Lubrilog

Considering the cost of a production shutdown of a kiln or a mill, this solution enables in 1h30 maximum and without production stop, to ensure a cleaning of the equipment and to extend its life time (by reducing abrasive wear) Download the documentation Our references Cement plants customers: LAFARGE HOLCIM, HEIDELBERG, VICAT, SECIL, etc Mining industry drivers and barriers to industrial energy efficiency: acase study of south africa’s cement finishing mill plant October 2020 In book: ADVANCES IN ENERGY RESEARCH (pp4572)DRIVERS AND BARRIERS TO INDUSTRIAL ENERGY ResearchGate one of the largest operating cost burdens for cement plants is often electricity, the drive system controlling the mills must be extremely energy efficient if operators are to produce finished materials at the lowest possible cost per ton Cement ball mill drive system options For ball mills in the cement industry, there are two Get Detail; Sicement Drives Whether for the Drives For Cement Mill staphbe

Power consumption of cement manufacturing plant

Fuel and electricity costs are the single largest variable production cost at cement mill plants Variable costs are typically about 50% of overall operating costs, so energy cost is usually the single largest production cost, besides raw materials Labor cost is relatively a small part of the Cement Manufacturing Plant Most of the energy usage is in cement production drives end 14/05/2020 According to the data we know, the total cost of a cement plant is estimated to be US$ 75 to US$ 100 per ton One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors, including the significant difference in cost of land, availability of limestone mines, etcCement Factory Cost How Much Does It Cost To Start A Demand for cement in the construction industry drives production and is thus an important determinant of cement subsector energy consumption and CO 2 emissions Initial estimates suggest that 43 Gt of cement were produced globally in 2020 This is a modest increase from 42 Gt the previous year, driven in large part by infrastructurerelated stimulus projects in China Cement – Analysis IEA

BIGGEST VERTICAL MILL IN THE WORLD OPERATING IN BRAZIL

BIGGEST VERTICAL MILL IN THE WORLD OPERATING IN BRAZIL Capacity increase at Barroso – significant reduction of total cost per ton of cement // LafargeHolcim, one of the global players in the cement industry, had decided to increase its production capacities in Latin America, more precisely in the existing cement works in Barroso, BrazilDrives for the Finish Mill Variable Frequency Drives in the Cement Industry Controlling fan fl ow by adjusting speed avoids wasting energy in adjustable dampers and louvers When large fl ows are involved and the motor energy consumption is signifi cant, varying the speed is the answer With large Every step of the way, from the quarry to the fi nished cement product, variable Drive Solutions for the Global Cement Industry TMEIC01/11/2014 Cement plants are one of the largest consumers of energy Their electrical energy costs account for about 15 20 percent of the total production cost The large fans and motors used in the production process consume a major part of electrical energy With the use of Variable Frequency Drives (VFDs) the energy consumption can be reduced fromAutomation of Kiln Mill Drive in Cement Industry using PLC

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL DRIVES

reliability and availability at competitive cost The first Gearless Mill Drive (GMD) with a power of 65 MW was installed 1969 in a cement milling process in the cement plant Le Havre in France In the first few years, the GMD was only used in the cement industry The GMD is also known as “wraparound motor” or “ringmotor” Almost 25 years later, the first GMD with 120 MW power A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, The hardness of clinker is important for the energy cost of the grinding process It depends both on the clinker's mineral composition and its thermal history The easiestground clinker mineral is alite, so highalite clinkers reduce grinding costs, although they are more expensive to make in Cement mill WikipediaWorking Cement Mill With The Use Of Electrical Drives Definition for cement mill in electric drives Gearless drives are especially suited for use in cement and ore mills conveyer belt systems as well as for mills ship drives and windpower facilities A pioneering innovation In 1970 Siemens developed the first gearless drive for the S dbayerisches PortlandZementwerk in 12 Definition For Cement Mill In Electric Drives