lead zinc ore mineral processing system mining process gypsum

2024-03-06T13:03:54+00:00

Gypsum Mining Processing Equipment Flow Chart

2 天前 Gypsum Mining Process Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boards 1 Mixed flotationlead zinc separation Process advantages: The flotation process performs two mixed flotation of lead and zinc under weak alkaline conditions, and separates lead and zinc under weak acid conditions The process of mixing lead and zinc twice can discard the tailings at one time and reduce metal loss In the leadzinc ore Lead Zinc Mining Solution Mineral ProcessingAbandoned lead and zine mines and chat piles in Galena, Cherokee County, that have since been reclaimed In 1870, the discovery of zinc ore in far southeastern Kansas marked the beginning of a century of lead and zinc mining in the Lead and zinc mining GeoKansas

Zinc Ore an overview ScienceDirect Topics

A leadzinc ore was treated at the rate of 100 t/h to an integrated system to produce concentrates of lead and zinc minerals A closed circuit was chosen so that the middling produced was retreated The average lead and zinc concentrations in each stream were: Zinc recovery from the Waelz kiln was 95% and the zinc oxide produced was directly leached in the zinc smelter which produced zinc metal The processing of stockpiled Shairmerden zinc oxide ore continues at the smelter although the mine is now closed due to accelerated mining and ore body depletion The analysis of the Shairmerden deposit is A Brief Summary of Zinc Oxide Processing Methods 1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1116 Gypsum Manufacturing United States

Zinc: smelting, producing and classificationMetalpedia

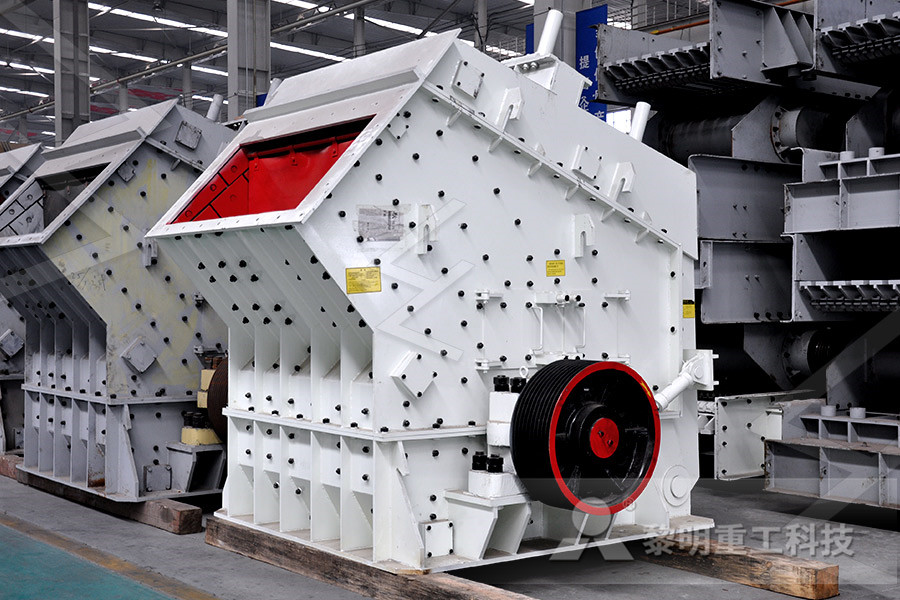

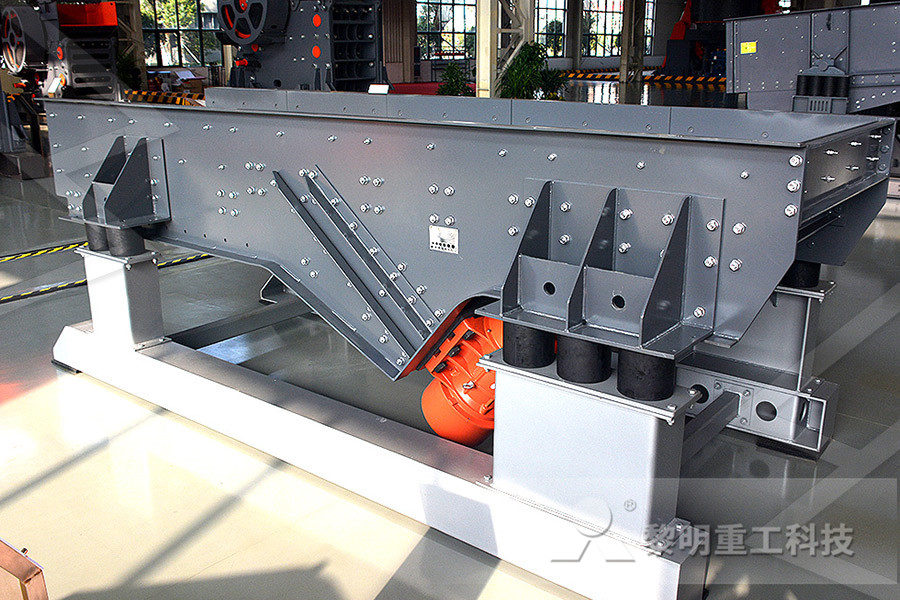

Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc The most common zinc concentrate processed is zinc sulfide, which is obtained by concentrating sphalerite using the froth flotation methodThere are two methods of smelting zinc: the pyrometallurgical process and the hydrometallurgical process (over 90% of hydrometallurgical In the process of crushing, JXSC Mining uses jaw crusher and applies the twostage crushing process In the process of screening, JXSC Mining uses simple and useful circular vibrating screen, which also have the features of large capacity, high efficiency, and convenient operation It is very suitable for screening of barite oreBaryte Mining Process Equipment Flow Cases JXSC A comprehensive recovery process for the selective separation and enrichment of copper, zinc and iron minerals from a polymetallic ore was developed, which consisted of copper flotation, zinc flotation, and iron magnetic separation, and the adsorption mechanism of the copper collector Z200 (OisopropylNethyl thionocarbamate) was also studied in this work The Minerals Free FullText A Comprehensive Recovery

(PDF) Integrating mining and mineral processing for

The integration of mining and mineral processing technologies into new advanced mining systems is considered to offer several benefits, including selective mining, reduction in waste, increased This article presents the results of studies of a lowwaste technology for processing enrichment tailings using a combined enrichment–hydrometallurgical method After washing the enrichment tailings from harmful products and reducing their size, multistage flotation of the crushed material of the enrichment tailings was carried out The use of a new reagent in the Optimization of Conditions for Processing of Lead–Zinc Introduction of Lead and Zinc Ore Lead is one of the earliest metals which were extracted from leadzinc ore by humans It is one of the soft metal, with bluegray, hardness 15, specific gravity of 1134, melting point 3274 ℃, boiling point 1750 ℃, good ductility, which is can be easy made of alloy with other metals such as zinc, tin, antimony , arsenic, etc Zinc is the Equipment for Lead and Zinc Mining Processing Plant

Zinc Ore an overview ScienceDirect Topics

A leadzinc ore was treated at the rate of 100 t/h to an integrated system to produce concentrates of lead and zinc minerals A closed circuit was chosen so that the middling produced was retreated The average lead and zinc concentrations in each stream were: MINING PROPOSAL SORBY HILLS SILVER LEAD ZINC PROJECT EAST KIMBERLEY, WESTERN AUSTRALIA NOVEMBER 2011 MINING PROPOSAL FOR THE CONSTRUCTION AND OPERATION OF THE SORBY HILLS SILVER LEAD ZINC PROJECT MINE SITE Tenements M80/197 M80/286 Prepared by Sorby Management Pty Ltd with the MINING PROPOSAL EPA WAFEECO Mining Capabilities Our equipment and solutions are used around the world in a variety of mining and mineral processing operations We’ve worked with everyone from process startups and entrepreneurs, to Fortune 100 companiesMining Mineral Processing Equipment

Mining Mineral Processing SciDev

Mining Mineral Processing SciDev is an industry leader in solid liquid separation in the mineral processing sector Our chemistries and professional services maximise the operational performance of mineral processing systems and ensure minimal water is Zircon Mining Mining of mineral sands can be by both dry mining and wet () mining methods In some countries, mineral sands products, principally titanium minerals, are also recovered from hard rock mining methods Dry mining is suitable where deposits are shallow, contain hard bands of rock, or are in a series of unconnected ore bodiesZircon Mining Process Equipment Flow Cases JXSC The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods

Advanced Process Control and Mineral

Advanced process control is a software tool that collects information from the process / field (supervision, historians, and control systems) applies the right control strategy (according to the process requirements) to deliver the Most zinc is used in the galvanizing steel process Other uses include the automotive, construction, electrical, and machinery industries Zinc compounds include agricultural chemicals, paints, pharmaceuticals, and rubber Refining Zinc concentration is usually done at the mine site prior to reaching the zinc processing plant (refinery)Mineral Processing Solutions Mining and processing of lead and zinc ores commenced in this area circa 1850 and continued until the 1970s The district's lead and zinc production ranked among the highest in the world Mining and ore processing produced approximately 500 million tons of wastes, with a sizeable portion of that waste remaining unsecured, estimated at 100 Lead, cadmium, and zinc concentrations in plaster and

A Deposit Model for Mississippi ValleyType LeadZinc

A Deposit Model for Mississippi ValleyType LeadZinc Ores 2 cm Sample of spheroidal sphalerite with dendritic sphalerite, galena, and iron sulfides (pyrite plus marcasite) from the Pomorzany mine Note the “up direction” is indicated by “snowontheroof” texture of galena and sphalerite alnong colloform layers of lightcolored spahlerite Introduction to Lead and Zinc Processing Lead and zinc can be produced pyrometallurgically or hydrometallurgically, depending on the type of ore used as a charge In the pyrometallurgical process, ore concentrate containing lead, zinc, or both is fed, in some cases after sintering, into a primary smelter Lead concentrations canPrecious Element Analysis in Lead and Zinc Processing Over 20 ore zones are mineable, each up to 14km long by 800m deep and from 4m to 48m wide As of mid2005, Xstrata reported that the underground Isa lead mine had proven reserves of 04Mt grading 59% zinc, Mount Isa Lead, Zinc and Silver Mine Mining

A Brief Summary of Zinc Oxide Processing Methods

Zinc recovery from the Waelz kiln was 95% and the zinc oxide produced was directly leached in the zinc smelter which produced zinc metal The processing of stockpiled Shairmerden zinc oxide ore continues at the smelter although the mine is now closed due to accelerated mining and ore body depletion The analysis of the Shairmerden deposit is Zinc smelting is the process of converting zinc concentrates (ores that contain zinc) into pure zinc The most common zinc concentrate processed is zinc sulfide, which is obtained by concentrating sphalerite using the froth flotation methodThere are two methods of smelting zinc: the pyrometallurgical process and the hydrometallurgical process (over 90% of hydrometallurgical Zinc: smelting, producing and classificationMetalpediaRasp is an underground mining operation with a surface processing facility that has average annual metal production of 30,000 tonnes of zinc metal in concentrate, 20,000 tonnes of lead metal in concentrate, and over 10 million ounces of silver in the lead concentrate Rasp Mine employs over 220 people directly with additional contract employmentRasp Mine CBH Resources

Introduction to Mineral Processing Sepro Labs

Introduction to Mineral Processing 5 30 Liberation and Comminution 31 Liberation In order to separate the minerals from gangue (the waste minerals), it is necessary to crush and grind the rock to unlock, or liberate, valuable minerals so that they are partially or fully exposed IN MINING MINERAL PROCESSING CIL CIP CIL is the simultaneous process of leaching and adsorption This process was specifically developed for the processing of gold ores containing “pregrobbing” materials ie organic carbon These materials reduce the gold yield by attracting the gold meant for the activated carbonIN MINING MINERAL PROCESSING AFX Holdings