flotation cell for mineral processing optimal performance

2021-02-15T17:02:07+00:00

Flotation Cells Mineral Processing Metallurgy

14/12/2015 Flotation Cell Design and Flotation Flowsheets The “SubA” Operates in three zones: in bottom zone, impeller thoroughly mixes and Combining the benefits of circular cells with the unique features of the patented DV™ mechanism, the RCS™ (Reactor Cell System) flotation technology has been developed to create ideal conditions to maximize flotation performance for all roughing, cleaning and scavenging duties The cell can be modified to handle high density slurriesRCS™ flotation solution OutotecFlotation circuit design has primarily relied on experience; to develop a system that automatically generates optimal layout for any given ore feed, there are two aspects needed to be addressed: circuit simulation and optimisation Development of mathematical models that simulate the otation process started shortly after its inventionFlotation Circuit Optimisation and Design

SIMULTANEOUS OPTIMIZATION OF FLOTATION

different applications in mineral processing, a grinding process and size separation process for hydrocyclone and froth recovery maximization for the flotation circuits The process parameters were controlled using a fuzzy logic based model and GA was used to determine the necessary condition for the optimal performance of the processes 11/01/2016 The bubbles of air, sucked or blown into the pulp in the flotation machines, become coated with mineral and rise to the surface where they collect in the form of a mineralized froth This primary concentrate, in which the bulk of the mineral is collected, continuously flows or is scraped over the lip of the machine into a collecting launder If a product clean enough to be Flotation Mineral Processing Metallurgy01/06/2006 Optimal selection of flotation circuits means finding the interconnections of several banks of flotation cells with one or more recycle streams such that one obtains the best possible performance Significant progress has been made in the optimization of flotation networksSimultaneous optimization of the performance of

TECHNICAL NOTES 9 FLOTATION mineraltech

Flotation is the most widely used mineral separation method It is the preferred method of mineral recovery for many of the most important minerals that are recovered and large tonnages of ore are processed by flotation annually The underlying principles of the flotation process are well established but it has proved to be unusually difficult to build quantitative predictive 04/07/2012 Although a bank is the simplest interconnection of cells in a circuit, ie, the tails of one cell is the feed to the next cell down the bank, how to operate each flotation cell in a way that the whole bank performance is optimized remains a challengeSignificant efforts have been made towards understanding the effect of operating variables on the flotation performance of An Overview of Optimizing Strategies for Flotation MDPI29/09/2021 Nalco Water, an Ecolab company, has announced the launch of Flotation 360, a holistic approach to flotation in mineral processing The solution combines Nalco Water’s advanced frother and collector chemistries with a worldwide technical service team and digital diagnostic tools that monitor the chemical, operational and mechanical levers influencing Ecolab Launches Complete EndtoEnd Flotation Optimization

Flotation data for the design of process plants Part 1

optimum ßotation process is reliant on four key factors:N understanding of the geology and associate miner alogical variations that impact on metallurgical Nperformance definition of the mining method and the relationship Nbetween the ore reserve and mine production evaluation of mineral and water chemistry which can Naffect the flotation process completion of adequate 01/06/2006 Optimal design of flotation plants depends on the quality of the raw ores and the desired final products and involves (i) the selection of appropriate flotation circuits, (ii) the sizing of the banks as well as the cell units, and (iii) fixing of the operating parameters Optimal selection of flotation circuits means finding the interconnections of several banks of flotation Simultaneous optimization of the performance of flotation ensure optimum performance This paper reviews selection methodology used for modern flotation tanks, the detailing the information required to ensure the best results The paper will also discuss various configuration and layout considerations and how these can impact future plant performance Key words: Flotation, Equipment Selection, Plant Design SELECTION OF MECHANICAL FLOTATION EQUIPMENT

Flotation bank air addition and distribution for optimal

Furthermore, it has been shown that when operating a cell at the air rate that yields the ‘Peak Air Recovery’ (PAR), an improvement in flotation performance, particularly mineral recovery, can Multiobjective Optimal Synthesis and Design of Froth Flotation Circuits for Mineral Processing, Using the Jumping Gene Adaptation of Genetic Algorithm December 2004 Authors:Multiobjective Optimal Synthesis and Design of Froth 20/12/2018 Froth Flotation machine plays an indispensable role in the mineral beneficiation process, flotation is susceptible to a number of factors during the process, including grinding fineness, slurry concentration, pulp pH, pharmaceutical system, aeration and agitation, flotation time, water quality and other process factors The factors that affect the flotation process are 7 Factors Affecting Froth Flotation Process JXSC Machine

Valueiterationbased Adaptive Optimal Reagents Control

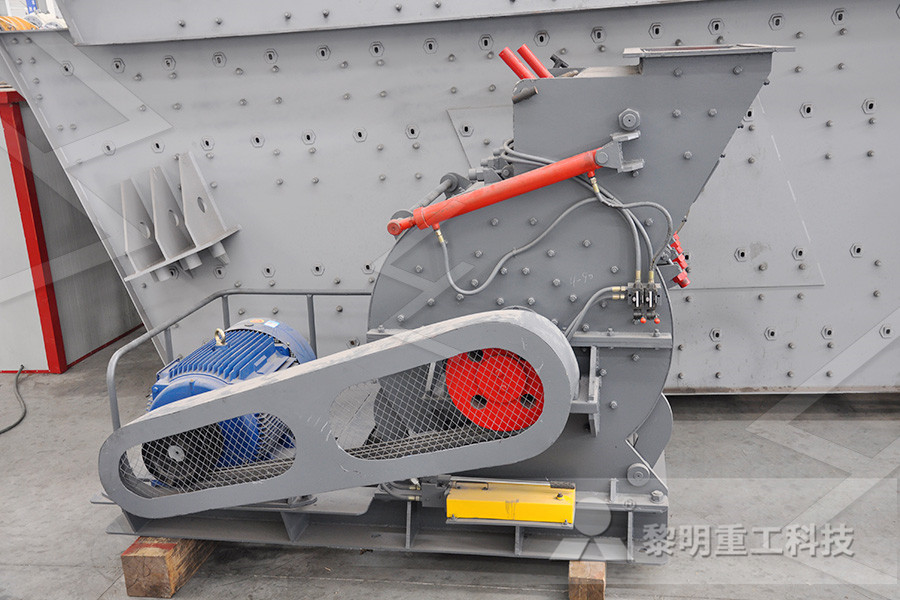

Antimony Flotation Process technique for mineral processing, by adding certain different chemical reagents in pulp to modify the mineral hydrophobic or hydrophilic properties [2] However, in order to obtain the desired flotation index, adjustment of reagents addition in practice are mainly relied on experienced operators, which may lead to poor flotation 12/06/2012 Performance, environmental compatibility and economy at the highest level The brand new JAWMAX 200 ® offers highly professional crushing performance with optimal transport dimensions and a weight of less than 28 tonsMineral Processingparticularly useful for processing finegrained ores that are not amenable to conventional gravity concentration Figure 1: The flotation system includes many interrelated components, and changes in one area will produce compensating effects in other areas (Klimpel, 1995) Froth flotation is a good example of an engineering “system”, in that the various important 1 Froth Flotation – Fundamental Principles

Coarse flotation aids sustainability Mining Magazine

14/07/2021 To achieve optimal recovery of coarser particles, mineral processing plants require a combination of new cell design along with tailored reagents and application knowhow, as optimal flotation performance relies on a careful balance of chemical, mechanical and operational factors09/08/2016 Flotation cell is widely used for separating nonferrous metal, black metal, noble metal, nonmetal mineral, raw body and materials of chemical industryHow is the flotation cell used for mineral processing 15/08/2019 Regular maintenance inspections help achieve optimal metallurgical performance in flotation machines Declining ore grades is one of the key challenges in the mining and minerals processing The demand for Regular maintenance inspections help achieve optimal

Application Flotation cell rpm monitoring

Application – Flotation cell rpm monitoring Applications Flotation cells are an essential component in platinum group mineral recovery processes and the optimal rotational speed is critical to efficient operation A Motornostix MXD Antimony Flotation Process technique for mineral processing, by adding certain different chemical reagents in pulp to modify the mineral hydrophobic or hydrophilic properties [2] However, in order to obtain the desired flotation index, adjustment of reagents addition in practice are mainly relied on experienced operators, which may lead to poor flotation Valueiterationbased Adaptive Optimal Reagents Control 20/12/2018 Froth Flotation machine plays an indispensable role in the mineral beneficiation process, flotation is susceptible to a number of factors during the process, including grinding fineness, slurry concentration, pulp pH, 7 Factors Affecting Froth Flotation Process JXSC

high performan mineral processing flotation cell machines

Oct 27, 2021and high performance flotation cell for mineral separation and high performance flotation cell for mineral separation Jun 5 2018 The incoming feed to the mechanical flotation machine is usually As might be expected the major advantage of such a machine is the high separation grade that can the understanding and performance of 12/06/2012 Performance, environmental compatibility and economy at the highest level The brand new JAWMAX 200 ® offers highly professional crushing performance with optimal transport dimensions and a weight of less than 28 tonsMineral Processingparticularly useful for processing finegrained ores that are not amenable to conventional gravity concentration Figure 1: The flotation system includes many interrelated components, and changes in one area will produce compensating effects in other areas (Klimpel, 1995) Froth flotation is a good example of an engineering “system”, in that the various important 1 Froth Flotation – Fundamental Principles

Machine Vision Based Production Condition Classification

Machine Vision Based Production Condition Classification and Recognition for Mineral Flotation Process Monitoring Jinping Liu School of Information Science Engineering, Central South University Changsha, Hunan, , PR China Email: ljp@163 Weihua Gui School of Information Science Engineering, Central South University Changsha, Hunan,