energy in beneficiation of pper production

2021-12-22T15:12:11+00:00

energy in beneficiation of copper production

27/10/2020 Before the beneficiation of copper ores, low energy consumption, light pollution and low production cost Chemical beneficiation of copper oxide ore Acid leaching—precipitation—flotation Scope of application: malachite, cuprite, tenorite, copper mine tailings, etc, except copper ore containing calcium magnesium carbonate gangueCopper Ore Beneficiation Technology Linkedin Primary and Secondary Copper Production 11 Primary Production 11 and as carbon footprints and savings per 100 000 tonnes of production Energy Requirement and Savings in Terajoules (TJ 100 000t) • only the process of producing the product material is for comparison and not extraction beneficiation and other ancillary Energy In Beneficiation Of Copper ProductionCopper Ore Beneficiation Technology In modern industry and daily life, copper has a wide range of application and demand It has an important and irreplaceable position in electric, marine, aviation, communication, Copper Beneficiation Process,Copper Refining Process

Energy In Beneficiation Of Copper Production

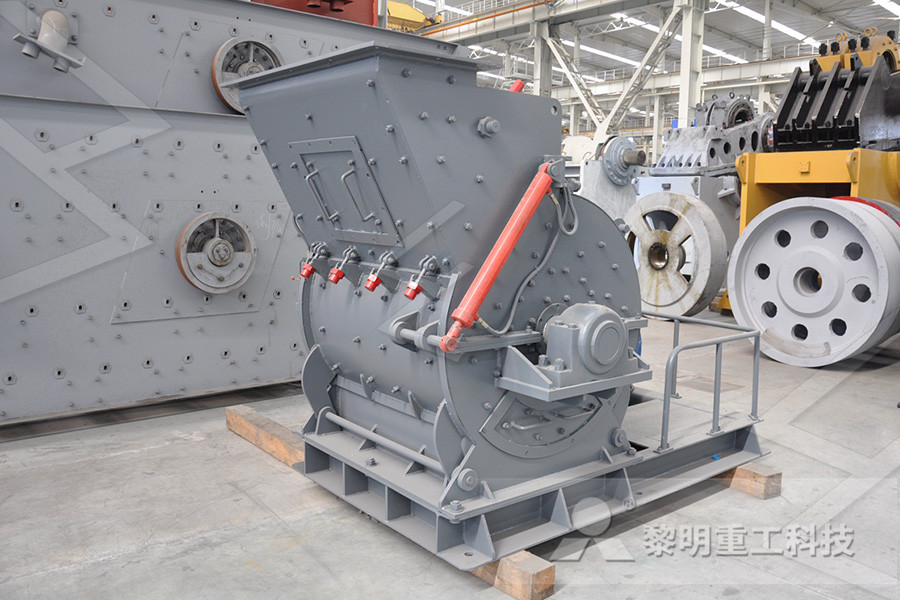

Energy In Beneficiation Of Copper Production FOB Reference Price: Get Latest Price Copper Beneficiation Process Of Copper Processing Plant Manufacturer Environmental protection Energysaving Low cost Production capacity 1501000td Rotary kiln is mainly used in the industrial field, such as mineral processing plants, cement plants, garbage disposal 25/01/2022 It has many advantages such as simple process flow, low investment, low energy consumption, light pollution and low production cost Chemical beneficiation of copper oxide ore Acid leaching—precipitation—flotationHow to Process Copper Ore: Beneficiation Methods and Figure 1: Overview of copper production Benefication process Figure 2: Overview of a typical beneficiation process at a concentrator Sulfidic copper ores are too dilute for direct smelting Smelting these materials would require too much energy and very large furnace capacities The copper ore coming from the mine (05 – 1 %COPPER Copper production TU Delft

Energy In Beneficiation Of Copper Production

Energy Use in the Copper Industry All aspects of copper production require energy, whether i n the form of electricity, explosives, or hydrocarbon fuels (diesel, gasoline, natural gas, fuel oil, coal, coke), or as the energy equivalent of materials consumed (e g, chemicals and steel grinding media) In 1977, the primary copper in Copper Beneficiation Process,Copper Copper production environmental impact GreenSpec World production of copper amounts to 12 million tons a year and exploitable reserves Beneficiation is the concentration of ore through separation into desirable Recycling a tonne of copper uses 20% of the energy that would be used toenergy in beneficiation of copper production Prominercopper production and beneficiation Primary copper production is a major activity in the mining sector It is highly energyintensive, ranking third in specific energy consumption (SEC) among the five major basic metals (aluminum, copper Current Energy Requirements in the Copper Producing Dec 20, 2013 An analysis of energy usage in the production of refined Energy In Beneficiation Of Copper Production

Pathways towards zeroemission copper mines

28/06/2020 “In general, the energy consumption in the primary copper process is dominated by the earlier stages of beneficiation This is due to the high energy demand requirement to crush and grind ore31/12/2019 Energy In Beneficiation Of Copper Production Beneficiation means converting the mined material into a valuable product it is the only way to exploit large deposits even lowgrade andor complex mineralogy it allows the mining of ores not only metal resources but all useful substances such as sands limestone granites barite fluorine etc the species enriched Energy In Beneficiation Of Copper ProductionAll aspects of copper production require energy, whether i n the form of electricity, explosives, or hydrocarbon fuels (diesel, gasoline, natural gas, fuel oil, coal, coke), or as the energy equivalent of materials consumed (e g, chemicals and steel grinding media) In 1977, the primary copper industry purchased 121trillion Btu of energy, or around 85 miIlion Btu per short ton of Chapter 7 Energy Use in the Copper Industry

How to Process Copper Ore: Beneficiation Methods and

25/01/2022 Before the beneficiation of copper ores, low energy consumption, light pollution and low production cost Chemical beneficiation of copper oxide ore Acid leaching—precipitation—flotation Scope of application: malachite, cuprite, tenorite, copper mine tailings, etc, except copper ore containing calcium magnesium carbonate gangue The ore is copper production environmental impact greenspec world production of copper amounts to 12 million tons a year and exploitable reserves beneficiation is the concentration of ore through separation into desirable recycling a tonne of copper energy in beneficiation of copper production01/04/1999 Copper production is, in many cases, also an important source of air pollutants It has been reported that in an actual flash copper smelter plant (100 000 tons/year of production capacity) only 25% of energy consumption goes to production, while the balance is used for environmental control [1] Thus, both energy use and environmental concerns Energy and environmental implications of copper production

Energy Efficiency Copper Hydrometallurgy

production included in smelter energy data Energy for delivery of supplies and reagents 24 Methodology –Disclaimer This generic analysis only considers energy consumption and does not take into account process capital and operating costs, nor other factors that may be important for process development and process selection for a particular mine site or application Process 20/11/2020 It is also energy intensive as energy is used in the whole life cycle of copper production, including mining, beneficiation, smelting and refining, not only in the directly processes but also through the indirectly production of inputs, eg electricity generation Globally, copper production requires around 600 million Gj of energy annually and Assessing the future environmental impacts of copper 23/11/2016 About 80% of global copper mine production comes sulphide ores that ore processed using grinding and flotation plants to produce concentrates for smelting The rest comes from mines using dump or heap leaching, solvent extraction and electrowinning to produce cathode copper Most copper mines are large, low grade, open pits Typically, these What drives GHG emissions from copper production

Energy Use in Metal Production CSIRO Publications

Energy Use in Metal Production John Rankin CSIRO, Process Science and Engineering, Australia Keywords: metals, embodied energy, primary metals, recycling, greenhouse Energy is consumed at all stages in the production of primary metals – mining, beneficiation and chemical extraction – directly in the processes and indirectly through the production of inputs (such as 21 Global copper production World copper production has been increasing at about 275% a year for over a hundred years, as shown in Figure 1, including by country in recent decades Over the past century, the status of dominant copper producer has shifted from the USA to 112 Future Greenhouse Gas Emissions from Copper31/12/2019 Energy In Beneficiation Of Copper Production Beneficiation means converting the mined material into a valuable product it is the only way to exploit large deposits even lowgrade andor complex mineralogy it allows the mining of ores not only metal resources but all useful substances such as sands limestone granites barite fluorine etc the species enriched Energy In Beneficiation Of Copper Production

Energy In Beneficiation Of Copper Production

Energy In Beneficiation Of Copper Production 2019 12 31 Energy In Beneficiation Of Copper Production Beneficiation means converting the mined material into a valuable product it is the only way to exploit large deposits even lowgrade andor complex mineralogy it allows the mining of ores not only metal resources but all useful substances such as sands limestone Beneficiation • Beneficiation is the concentration of ore through separation into desirable mineral the part of the ore that is useable and gangue (pronounced ‘gang’) – the part of the ore that is commercially worthless 3 Energy Primary copper production is a major activity in the mining sector It is highly energy intensiveEnergy In Beneficiation Of Copper Production28/01/2022 The flows of materials, energy and emissions linked to the production of copper are in part defined by the geological features of the copper deposit The ore grade is negatively correlated with the amount of energy required to obtain the copper concentrate (Memary et al 2012 ; MorenoLeiva et al 2017 ), and there are other factors affecting it (eg depth of a Environmental assessment of copper production in Europe

Energy Efficiency Copper Hydrometallurgy

production included in smelter energy data Energy for delivery of supplies and reagents 24 Methodology –Disclaimer This generic analysis only considers energy consumption and does not take into account process capital and operating costs, nor other factors that may be important for process development and process selection for a particular mine site or application Process 26 Sep 2018 Production of electric and hybrid cars and buses is expected to rise from It may be possible to cut the energy needed for making copper by 20 Copper Energygov Energy and Environmental Profile of the US Mining Industry 5 Copper Approximately half of copper beneficiation occurs through dump leaching, while aenergy in beneficiation of copper productionenergy in beneficiation of copper production Energy and Environmental Profile of the US Mining Industry Copper beneficiation may consists of: crushing and grinding, washing, filtration, sorting Gold,Silver,Copper,Lead,Zinc Ore Beneficiation Gold,Silver,Copper,Lead,Zinc Ore Beneficiation Plant,With High Concentrate (factory Offer) , Find Complete Details about copper production and beneficiation

production copper production and beneficiation

Copper production environmental impact Greenspec • World production of copper amounts to 12 million tons a year and exploitable reserves are around 300 million tons About 2 million tons a year are reclaimed by recycling (source EPA) World copper production 1900 2012 • “We are at a time where putting two or three megamines into production does not even keep up with 23/11/2016 About 80% of global copper mine production comes sulphide ores that ore processed using grinding and flotation plants to produce concentrates for smelting The rest comes from mines using dump or heap leaching, solvent extraction and electrowinning to produce cathode copper Most copper mines are large, low grade, open pits Typically, these What drives GHG emissions from copper production Energy Use in Metal Production John Rankin CSIRO, Process Science and Engineering, Australia Keywords: metals, embodied energy, primary metals, recycling, greenhouse Energy is consumed at all stages in the production of primary metals – mining, beneficiation and chemical extraction – directly in the processes and indirectly through the production of inputs (such as Energy Use in Metal Production CSIRO Publications